The Ultimate Guide To Interlock Block Machine Prices

Are you considering investing in an interlock block machine but unsure about the costs involved? Look no further! Our comprehensive guide provides invaluable insights into everything you need to know about interlock block machine prices. From different types of machines to factors that influence pricing, we break down all the essential information to help you make an informed decision. Read on to unlock the secrets to finding the best deals on interlock block machines.

- Understanding the factors that influence interlock block machine prices

Interlock block machines are an essential piece of equipment for those in the construction industry looking to create strong and durable interlocking blocks for building projects. However, the prices of these machines can vary widely depending on a number of factors. In this ultimate guide to interlock block machine prices, we will delve deep into the various factors that influence the cost of these machines, helping you to make an informed decision when purchasing one for your business.

One of the primary factors that impact interlock block machine prices is the capacity of the machine. Machines with higher capacities are able to produce more blocks in a shorter amount of time, making them ideal for larger construction projects. However, these machines tend to come with a higher price tag compared to those with smaller capacities. The size of the blocks that the machine can produce also plays a role in determining the price, as machines that are able to create larger or more complex blocks typically cost more.

Another key factor that influences interlock block machine prices is the level of automation and technology incorporated into the machine. Machines that are fully automated and equipped with the latest technological advancements are able to streamline the block production process and increase efficiency. However, this advanced technology often comes at a premium, resulting in higher prices for these machines. On the other hand, manual or semi-automatic machines may be more affordable but require more labor and time to operate.

The brand and reputation of the manufacturer also play a significant role in determining the price of interlock block machines. Established and reputable brands with a track record of producing high-quality machines may charge a premium for their products. However, these machines are often more reliable and durable, offering long-term value for the investment. On the other hand, lesser-known brands may offer lower prices but come with a higher risk of lower quality and reliability.

Additionally, the location and market demand can also impact interlock block machine prices. Machines manufactured in countries with lower labor and production costs often have lower price tags compared to those produced in more developed countries. Additionally, high demand for interlock block machines in a particular market can drive up prices due to limited availability.

In conclusion, the price of interlock block machines is influenced by a variety of factors including capacity, technology, brand reputation, and market demand. By understanding these factors, you can make an informed decision when purchasing a machine for your construction business. Remember to consider your specific needs and budget constraints to find the best machine that offers the greatest value for your investment.

- Comparing different types and models of interlock block machines

Interlock block machines are essential equipment in the construction industry, as they are used to produce interlocking blocks that are then used to build durable and sturdy structures. When it comes to purchasing an interlock block machine, one of the most important factors to consider is the price. In this comprehensive guide, we will compare different types and models of interlock block machines to help you make an informed decision.

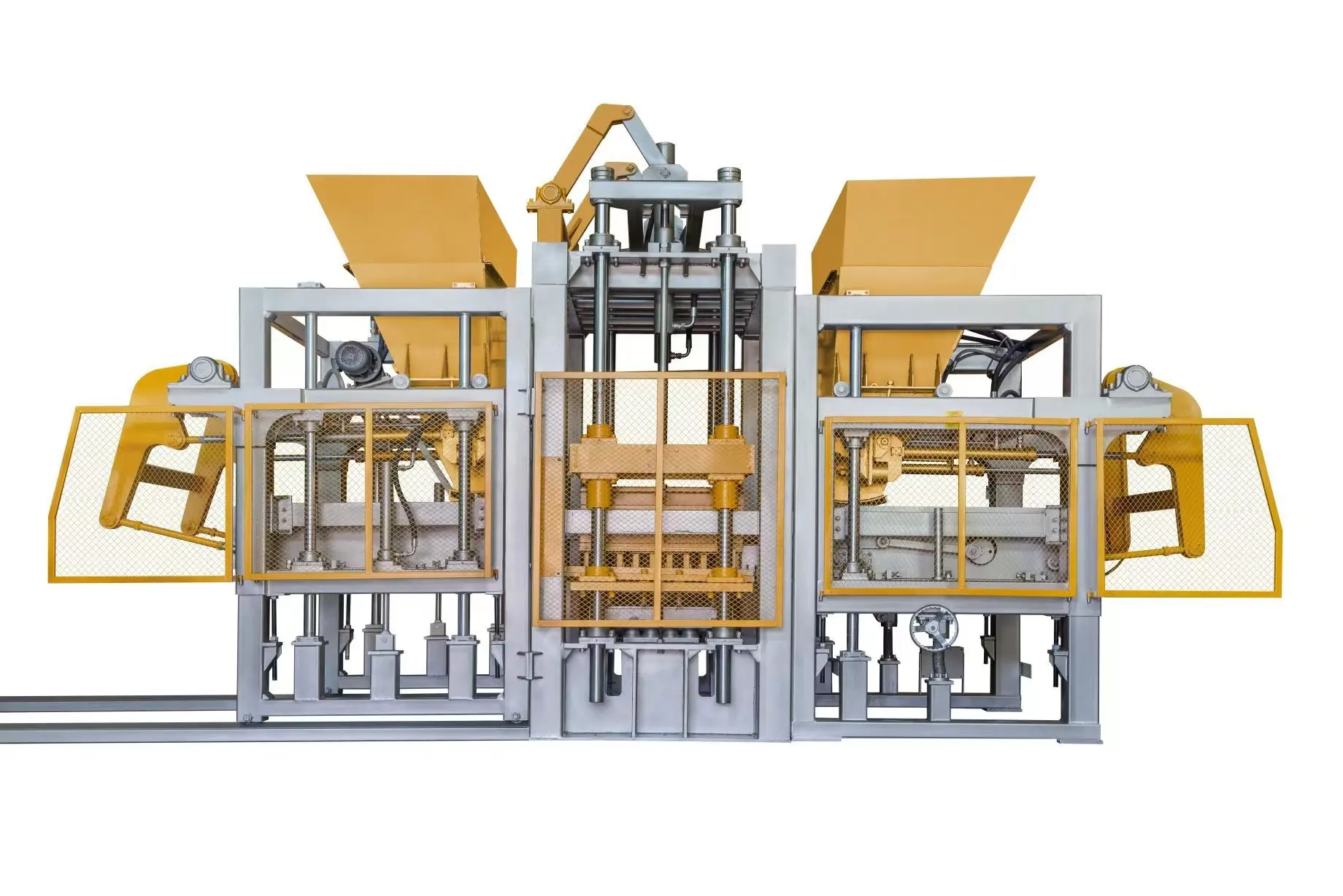

There are several factors that can influence the price of an interlock block machine, including the type of machine, its production capacity, and the brand. The most common types of interlock block machines are manual, semi-automatic, and fully automatic. Manual machines are the most affordable option, but they require more labor and are slower to operate. Semi-automatic machines offer a good balance between price and productivity, while fully automatic machines are the most expensive but also the most efficient.

In terms of production capacity, interlock block machines can vary greatly. Some machines are designed for small-scale projects and have a lower production capacity, while others are capable of producing a large number of blocks in a short amount of time. The price of the machine will depend on its production capacity, with higher capacity machines generally costing more.

When comparing different models of interlock block machines, it is important to consider the features and specifications of each machine. Some machines may have additional features such as automatic lubrication systems, vibrating tables, and hydraulic systems, which can increase the overall price. It is important to assess your needs and budget to determine which features are essential for your project.

In addition to the type and model of the machine, the brand can also impact the price of an interlock block machine. Some well-known brands may have higher prices due to their reputation for quality and reliability. However, there are also smaller, lesser-known brands that offer competitive prices without compromising on performance.

Overall, when considering the price of an interlock block machine, it is important to weigh the cost against the features, production capacity, and brand reputation. By comparing different types and models of interlock block machines, you can make an informed decision that meets your needs and budget requirements. Remember to consider factors such as maintenance costs, spare parts availability, and after-sales support when making your final decision.

- Finding the best deals and discounts on interlock block machines

Interlock block machines have become increasingly popular in the construction industry due to their ability to quickly and efficiently produce interlocking concrete blocks. However, with the growing demand for these machines, it is important for construction companies to find the best deals and discounts on interlock block machines. In this comprehensive guide, we will explore everything you need to know about interlock block machine prices and how to find the best deals in the market.

When it comes to interlock block machine prices, there are a few key factors to consider. The first factor to consider is the type of interlock block machine you are looking to purchase. There are various types of interlock block machines available in the market, ranging from manual machines to fully automatic machines. The price of these machines can vary depending on their size, capacity, and level of automation. It is important to determine your specific needs and budget constraints before making a purchase.

Another important factor to consider when it comes to interlock block machine prices is the brand and reputation of the manufacturer. It is always recommended to purchase interlock block machines from reputable manufacturers with a proven track record of producing high-quality machines. While these machines may come at a higher price point, they are often more reliable and durable in the long run, ultimately saving you money on maintenance and repairs.

In addition to the type of machine and manufacturer, you should also consider the location and shipping costs when determining the overall price of an interlock block machine. If you are purchasing the machine from an overseas manufacturer, you may incur additional costs for shipping, customs duties, and taxes. It is important to factor in these additional costs when comparing prices from different manufacturers.

Now that we have discussed some key factors to consider when it comes to interlock block machine prices, let's explore how to find the best deals and discounts on these machines. One of the best ways to find discounted prices on interlock block machines is to shop around and compare prices from multiple manufacturers. By contacting different manufacturers and suppliers, you can negotiate prices and potentially secure a better deal.

Another way to find discounts on interlock block machines is to attend trade shows and exhibitions where manufacturers showcase their latest products. These events often feature special promotions and discounts for attendees, making it a great opportunity to find a good deal on an interlock block machine.

In conclusion, finding the best deals and discounts on interlock block machines requires careful consideration of various factors such as the type of machine, manufacturer reputation, and additional costs. By doing thorough research and comparing prices from different manufacturers, you can find a quality interlock block machine at a competitive price.

- Tips for negotiating prices with interlock block machine suppliers

Interlock block machines have become a popular choice for construction projects due to their efficiency and durability. However, one of the main concerns when purchasing an interlock block machine is the price. Negotiating prices with suppliers can be a daunting task, but with the right tips and strategies, buyers can ensure they are getting the best deal possible.

When it comes to negotiating prices with interlock block machine suppliers, there are a few key tips to keep in mind. The first step in the negotiation process is to do thorough research on the market prices for interlock block machines. By understanding the average price range for these machines, buyers can have a better idea of what to expect and can use this information as leverage during negotiations.

Once buyers have a good understanding of the market prices, the next step is to prepare a budget. It is important to have a clear budget in mind before entering into negotiations with suppliers. This will help buyers stay within their financial limits and avoid overspending on an interlock block machine.

Another important tip for negotiating prices with interlock block machine suppliers is to be willing to walk away if the price is not right. Suppliers may try to pressure buyers into making a purchase, but it is important to stand firm and be prepared to walk away if the price is not negotiable. By showing suppliers that buyers are serious about getting the best deal, they may be more willing to lower their prices.

Additionally, buyers should be prepared to negotiate other aspects of the sale, such as payment terms and delivery options. Suppliers may be more willing to lower their prices if buyers are flexible on these terms. It is important to keep an open mind and consider all options during the negotiation process.

Overall, negotiating prices with interlock block machine suppliers can be a challenging task, but with the right tips and strategies, buyers can ensure they are getting the best deal possible. By doing thorough research, setting a budget, being willing to walk away, and negotiating other aspects of the sale, buyers can successfully negotiate prices with suppliers and get the interlock block machine they need at a fair price.

- Ensuring you get the most value for your money when purchasing an interlock block machine

Interlock block machines are a popular choice for those in the construction industry looking to streamline the process of creating interlocking blocks for various projects. However, with a wide range of options available on the market, it can be challenging to determine which machine offers the best value for your money. In this ultimate guide to interlock block machine prices, we will explore the key factors to consider when purchasing a machine to ensure that you get the most value for your investment.

One of the first things to consider when comparing interlock block machine prices is the type of machine that best suits your needs. There are several different types of interlock block machines available, including manual, semi-automatic, and fully automatic machines. Manual machines are the most affordable option but require more manual labor, while fully automatic machines offer more efficient production but come with a higher price tag. It is essential to assess your production needs and budget to determine which type of machine is the best fit for your operation.

Another key factor to consider when evaluating interlock block machine prices is the production capacity of the machine. Production capacity refers to the number of interlocking blocks that the machine can produce in a given period, typically measured in blocks per hour. Machines with higher production capacities are generally more expensive but can significantly increase your output and efficiency in the long run. It is crucial to assess your production requirements and choose a machine with a production capacity that aligns with your needs to ensure that you are getting the most value for your money.

In addition to considering the type and production capacity of the interlock block machine, it is also essential to pay attention to the quality and durability of the machine. Investing in a high-quality machine from a reputable manufacturer may come with a higher price tag initially, but it can save you money in the long run by reducing maintenance and repair costs. It is crucial to research different manufacturers and read reviews from other customers to ensure that you are purchasing a reliable and durable machine that will provide long-term value for your investment.

When comparing interlock block machine prices, it is also important to consider any additional features or accessories that come with the machine. Some machines may come with additional features such as hydraulic systems, vibration systems, or block stacking units that can enhance efficiency and productivity. While these features may increase the price of the machine, they can also provide added value by improving the overall performance and output of the machine. It is important to assess the benefits of these additional features and determine whether they are worth the extra cost based on your specific production needs.

Overall, when purchasing an interlock block machine, it is essential to carefully consider the type, production capacity, quality, and additional features of the machine to ensure that you are getting the most value for your money. By conducting thorough research, comparing prices, and evaluating your specific production requirements, you can make an informed decision that will benefit your operation in the long term. In conclusion, evaluating interlock block machine prices based on these key factors will help you make a smart investment that will enhance your productivity and efficiency in the construction industry.

Conclusion

In conclusion, after delving into "The Ultimate Guide to Interlock Block Machine Prices," it is clear that investing in a quality interlock block machine is essential for any construction business looking to streamline their production process and improve efficiency. With 18 years of experience in the industry, our company is well-equipped to provide you with the expert guidance and top-of-the-line machines necessary to take your business to the next level. By carefully considering factors such as machine capacity, automation features, and maintenance requirements, you can confidently make the best decision for your specific needs. Don't wait any longer – invest in a high-quality interlock block machine today and watch your business thrive!